Skylar Tibbits

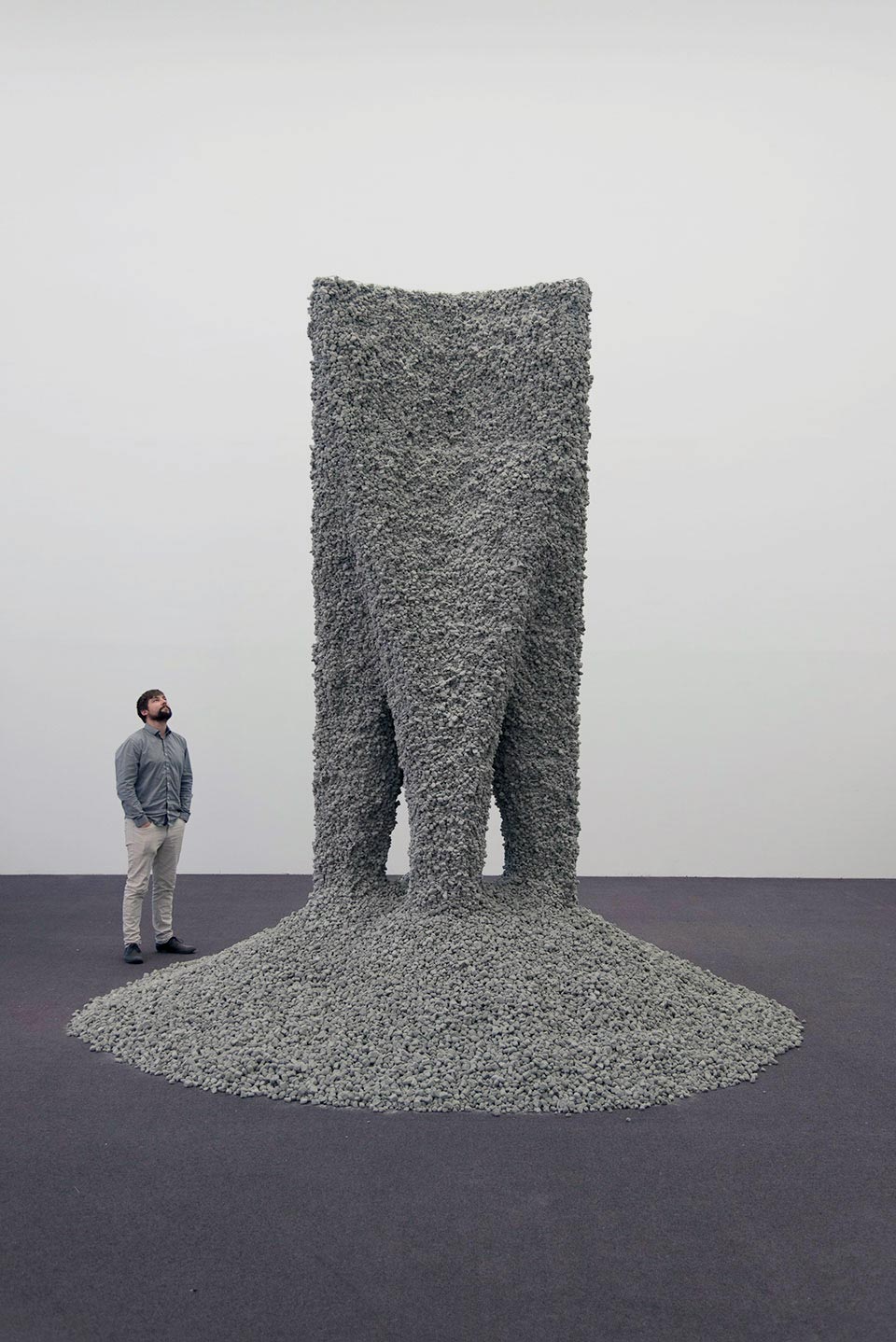

Aerial Assemblies

Self-Assembly is a process by which disordered parts build an ordered structure through local interaction. We have demonstrated that this phenomenon is scale-independent and can be utilized for self-constructing and manufacturing systems at nearly every scale. We have also identified the key ingredients for self-assembly as a simple set of responsive building blocks, energy and interactions that can be designed within nearly every material and machining process available. Self-assembly promises to enable breakthroughs across every applications of biology, material science, software, robotics, manufacturing, transportation, infrastructure, construction, the arts, and even space exploration.