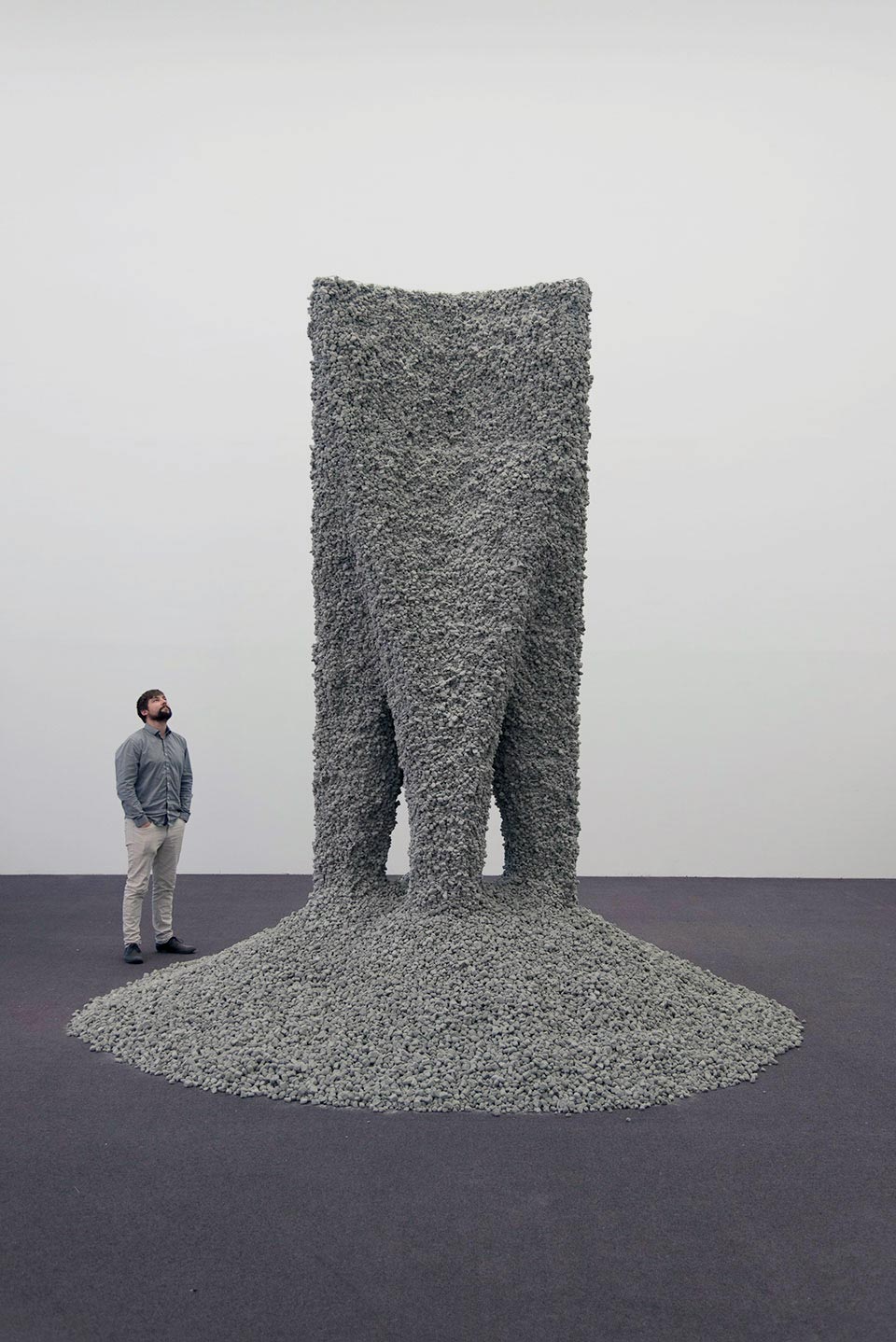

Skylar Tibbits

Rock Print

The world has been “about to be revolutionized” by 3D printing for years now, but aside from rapid prototyping, 3D selfies, and the occasional gimmicky 3D-printed house, we don’t see much of it every day. So why hasn’t this technology revolutionized modern infrastructure? One reason is that it still has to compete with concrete, one of the cheapest, most versatile, and efficiently delivered materials in the history of architecture. At the Chicago Architecture Biennial, Self-Assembly Lab at MIT and Gramazio Kohler Research of ETH Zurich showed off a process that might finally one-up concrete, using only a 3D printing extruder, rocks, string, and smart design.