Driessens & Verstappen

Breed

Breed (1995-2007) is a computer program that uses artificial evolution to grow very detailed sculptures. The purpose of each growth is to generate by cell division from a single cell a detailed form that can be materialised. On the basis of selection and mutation a code is gradually developed that best fulfils this “fitness” criterion and thus yields a workable form. The designs were initially made in plywood. Currently the objects can be made in nylon and in stainless steel by using 3D printing techniques. This automates the whole process from design to execution: the industrial production of unique artefacts.

Computers are powerful machines to harness artificial evolution to create visual images. To achieve this we need to design genetic algorithms and evolutionary programs. Evolutionary programs allow artefacts to be “bred”, rather than designing them by hand. Through a process of mutation and selection, each new generation is increasingly well adapted to the desired “fitness” criteria. Breed is an example of such software that uses Artificial Evolution to generate detailed sculptures. The algorithm that we designed is based on two different processes: cell-division and genetic evolution.

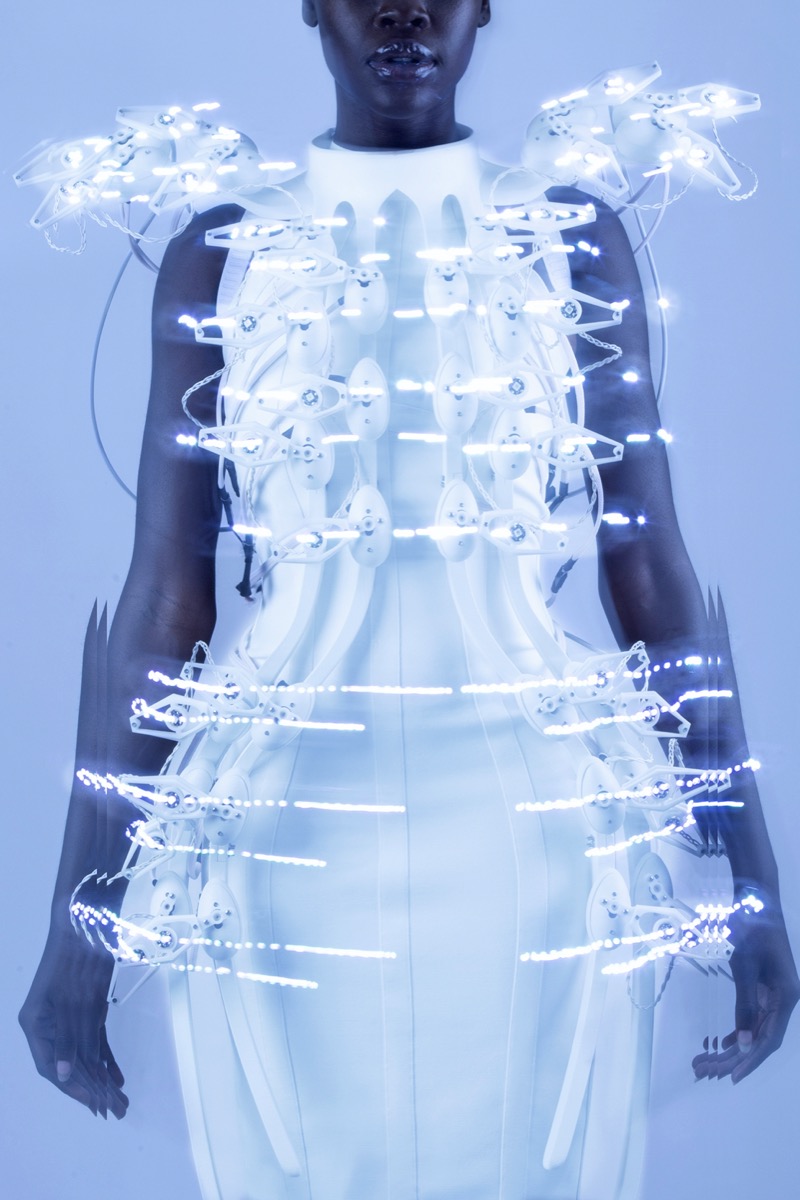

ANOUK WIPPRECHT

PANGOLIN DRESS

The Pangolin Scales Project demonstrates a 1.024 channel BCI (Brain-Computer Interface) that is able to extract information from the human brain with an unprecedented resolution. The extracted information is used to control the Pangolin Scale Dress interactively into 64 outputs.The dress is also inspired by the pangolin, cute, harmless animals sometimes known as scaly anteaters. They have large, protective keratin scales covering their skin (they are the only known mammals with this feature) and live in hollow trees or burrows.As such, Pangolins and considered an endangered species and some have theorized that the recent coronavirus may have emerged from the consumption of pangolin meat.Wipprecht’s main challenge in the project’s development was to not overload the dress with additional weight. She teamed up 3D printing experts Shapeways and Igor Knezevic in order to create an ‘exo-skeleton’ like dress-frame (3mm) that was light enough to be worn but sturdy enough to hold all the mechanics in place

Szymon Kaliski

Fabfungus

FabFungus is a physical installation inspired by questions of digital life and cellular growth. FabFungus is also a computational tool for creating digital structures grown out with a simulated process. It is also a manifestation of couple of these forms, brought to physical reality through imperfect 3D printing.

Zaha Hadid Architects

bow chair

designed by Zaha Hadid Architects, Ross Lovegrove and Daniel Widrig

BR41N.IO

Mindscapes

The BR41N.IO Hackathon brings together engineers, programmers, physicians, designers, artists or fashionistas, to collaborate intensively as an interdisciplinary team. They plan and produce their own fully functional EEG-based Brain-Computer Interface headpiece to control a drone, a Sphero or e-puck robot or an orthosis with motor imagery. Whenever they think of a right arm movement, their device performs a defined action. The artists among the hackers make artful paintings or post and tweet a status update. And hackers who are enthusiasts in tailoring or 3D printing give their BCI headpiece an artful and unique design. And finally, kids create their very own ideas of an interactive head accessory that is inspired by animals, mythical creatures or their fantasy.

Behnaz Farahi

Synapse

Synapse is a 3D-printed helmet which moves and illuminates according to brain activity[…] The main intention of this project is to explore the possibilities of multi-material 3D printing in order to produce a shape-changing structure around the body as a second skin. Additionally, the project seeks to explore direct control of the movement with neural commands from the brain so that we can effectively control the environment around us through our thoughts. The environment therefore becomes an extension of our bodies. This project aims to play with the intimacy of our bodies and the environment to the point that the distinction between them becomes blurred, as both have ‘become’ a single entity. The helmet motion is controlled by the Eletroencephalography (EEG) of the brain. A Neurosky’s EEG chip and Mindflex headset have been modified and redesigned in order to create a seamless blend between technology and design.

Alexis Walsh and Ross Leonardy

The Spire dress

Alexis Walsh is a designer and artist based in New York City. Through the exploration of emerging technologies including 3D printing and digital modeling, integrated with traditional handcraft, Alexis utilizes an interdisciplinary approach to push the boundaries of fashion design. Alexis graduated with honors from Parsons The New School for Design.

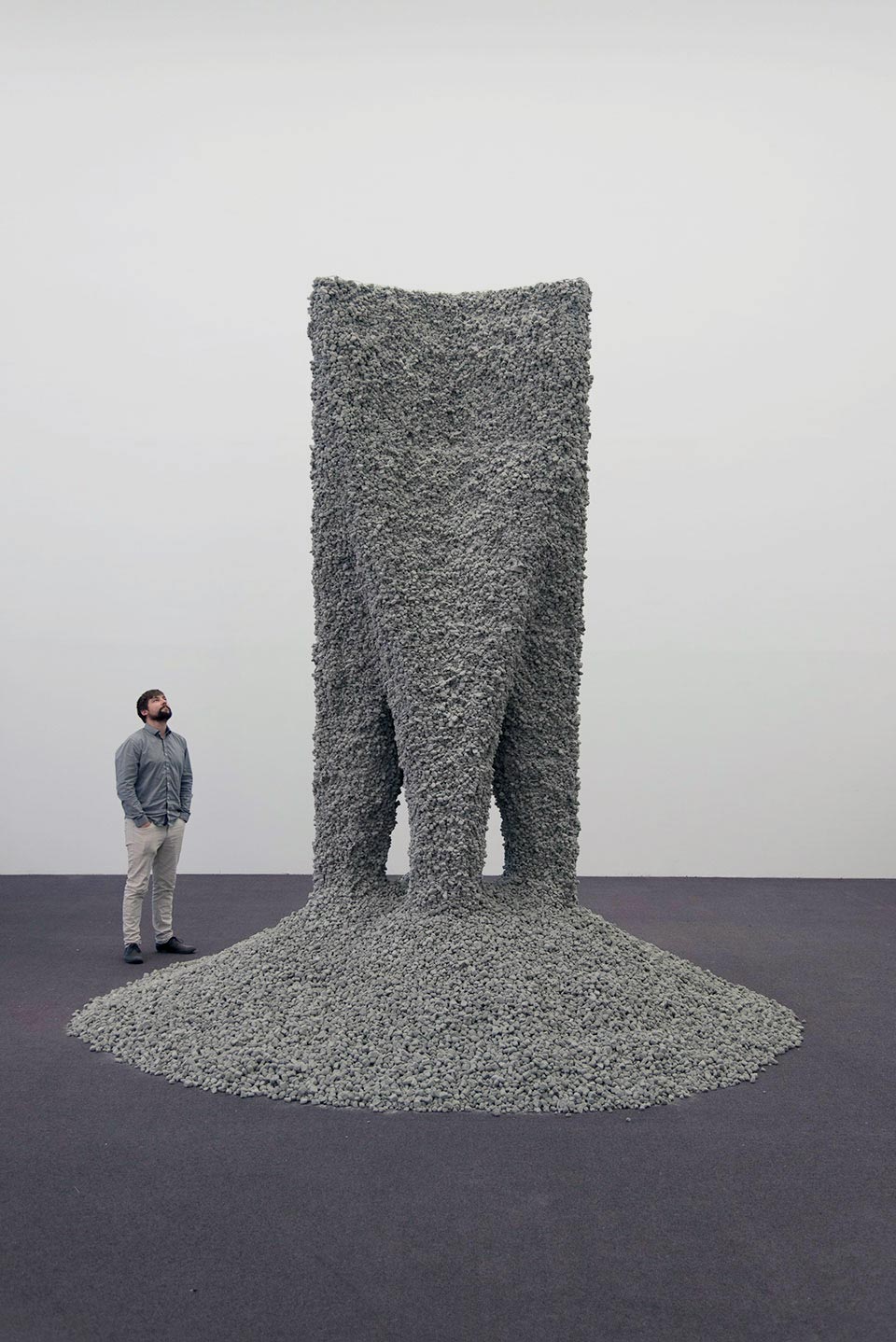

Skylar Tibbits

Rock Print

The world has been “about to be revolutionized” by 3D printing for years now, but aside from rapid prototyping, 3D selfies, and the occasional gimmicky 3D-printed house, we don’t see much of it every day. So why hasn’t this technology revolutionized modern infrastructure? One reason is that it still has to compete with concrete, one of the cheapest, most versatile, and efficiently delivered materials in the history of architecture. At the Chicago Architecture Biennial, Self-Assembly Lab at MIT and Gramazio Kohler Research of ETH Zurich showed off a process that might finally one-up concrete, using only a 3D printing extruder, rocks, string, and smart design.

MIT Media Lab

Hybrid living materials (HLMs)

A method for printing 3D objects that can control living organisms in predictable ways has been developed by an interdisciplinary team of researchers at MIT and elsewhere. The technique may lead to 3D printing of biomedical tools, such as customized braces, that incorporate living cells to produce therapeutic compunds such as painkillers or topical treatments, the researchers say.

Jun Kamei

Amphibio

AMPHIBIO is made out of a special porous hydrophobic material which supports underwater breathing by replenishing oxygen from the surrounding water and dissipating carbon dioxide which accumulate in the system, inspired from the gill of water diving insects. The material can be shaped in complex form using 3D printing. Patent pending.

Ronan & Erwan Bouroullec

17 Screens

The 17 Screens collection of partitions is the result of a year of research and development by the pair, and brings together traditional craft methods with technology such as 3D printing. The duo worked with French ceramic craftsmen, as well as tile brand Rombina and glass specialist Glas Italia. The pieces are based on line drawings by Ronan and Erwan Bouroullec, and partly inspired by Ronan’s visits to Bretagne to observe natural shapes and formations – including trees, mildew, and plants.

DESIGN STUDIO EMERGING OBJECTS

设计工作室新兴对象

Saltygloo

American studio Emerging Objects 3D-printed this pavilion using salt harvested from San Francisco Bay. “The structure is an experiment in 3D printing using locally harvested salt from the San Francisco Bay to produce a large-scale, lightweight, additive manufactured structures,” said Ronald Rael and Virginia San Fratello of additive manufacturing startup Emerging Objects. They explained that 500,000 tonnes of sea salt are harvested each year in the San Francisco Bay Area using power from the sun and wind. “The salt is harvested from 109-year-old salt crystallisation ponds in Redwood City,” they said. “These ponds are the final stop in a five-year salt-making process that involves moving bay water through a series of evaporation ponds. In these ponds the highly saline water completes evaporation, leaving 8-12 inches of solid crystallised salt that is then harvested for industrial use.”

Markus Kayser

Solar Sinter

In this experiment sunlight and sand are used as raw energy and material to produce glass objects using a 3D printing process, that combines natural energy and material with high-tech production technology. Solar-sintering aims to raise questions about the future of manufacturing and triggers dreams of the full utilization of the production potential of the world’s most efficient energy resource – the sun. Whilst not providing definitive answers, this experiment aims to provide a point of departure for fresh thinking.

Hiroshi Sugihara

Ready to crawl

Ready to Crawl is a project of 3D-printed organic-like robots. By printing everything except the motor as one unit, the robots are born with a completed shape like real creatures. After the robots have been printed by a selective laser sintering machine, excess nylon powder is removed, a motor is inserted, and then they start crawling.

Designer: Hiroshi Sugihara

Project director: Shunji Yamanaka