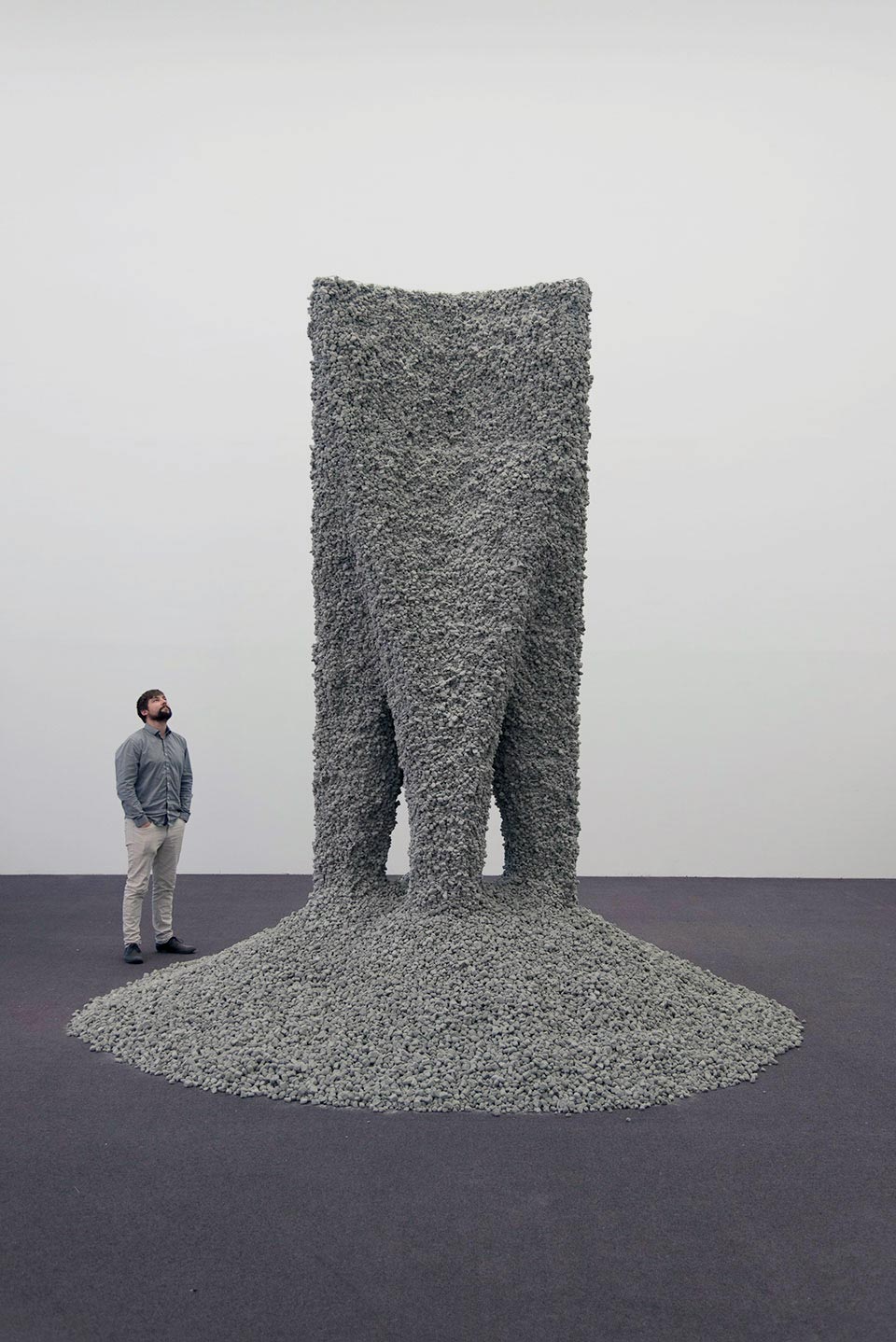

Driessens & Verstappen

Breed

Breed (1995-2007) is a computer program that uses artificial evolution to grow very detailed sculptures. The purpose of each growth is to generate by cell division from a single cell a detailed form that can be materialised. On the basis of selection and mutation a code is gradually developed that best fulfils this “fitness” criterion and thus yields a workable form. The designs were initially made in plywood. Currently the objects can be made in nylon and in stainless steel by using 3D printing techniques. This automates the whole process from design to execution: the industrial production of unique artefacts.

Computers are powerful machines to harness artificial evolution to create visual images. To achieve this we need to design genetic algorithms and evolutionary programs. Evolutionary programs allow artefacts to be “bred”, rather than designing them by hand. Through a process of mutation and selection, each new generation is increasingly well adapted to the desired “fitness” criteria. Breed is an example of such software that uses Artificial Evolution to generate detailed sculptures. The algorithm that we designed is based on two different processes: cell-division and genetic evolution.