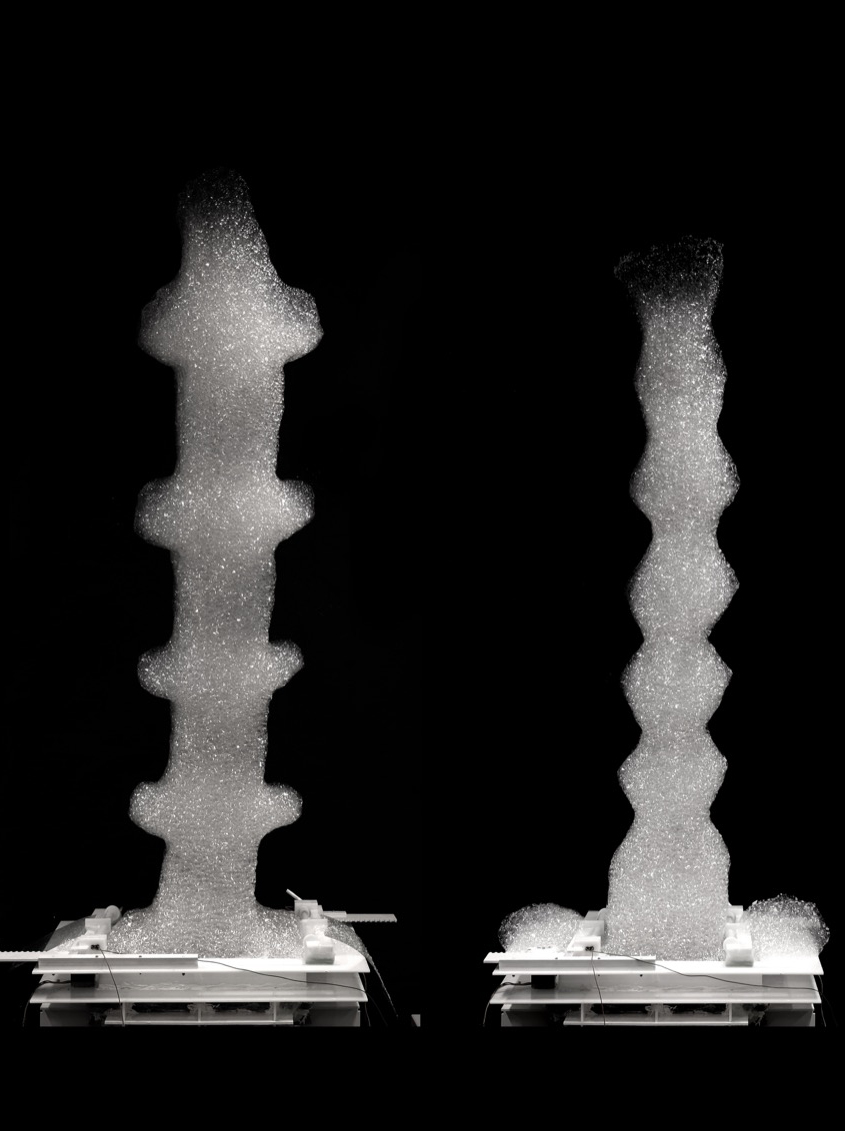

NERI OXMAN AND CHRISTOPH BADER & DOMINIK KOLB

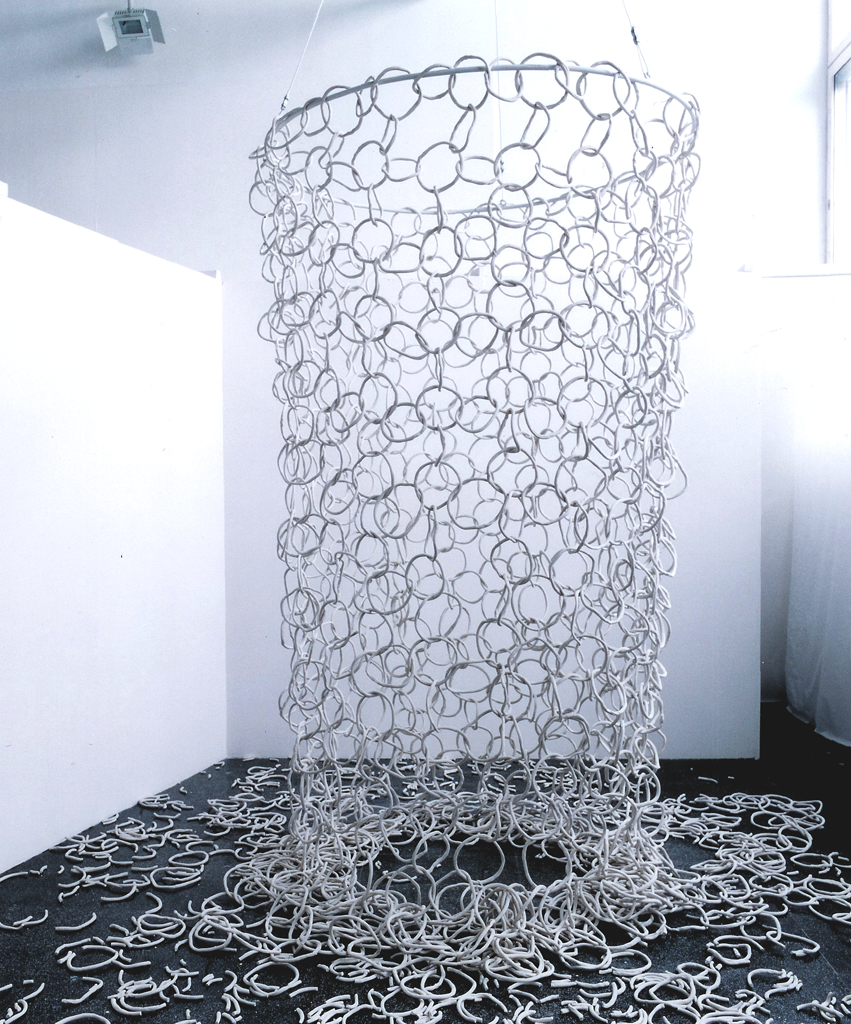

Vagabonds

De nombreux projets d’Oxman utilisent des techniques d’impression et de fabrication 3D. Ils incluent le pavillon de la soie, filé par des vers à soie sur un cadre en nylon, 3 Ocean Pavilion, une plate-forme de fabrication à base d’eau qui a construit des structures de chitosane, 4 G3DP, la première imprimante 3D pour verre optiquement clair, et un ensemble de verre produit par elle, 5 et collections de vêtements imprimés en 3D et utilisables dans les défilés haute couture. Voyager vers des destinations au-delà de la planète Terre implique de voyager dans des paysages hostiles et des environnements mortels. La gravité écrasante, l’air ammoniacal, l’obscurité prolongée et les températures qui feraient bouillir le verre ou geleraient le dioxyde de carbone, éliminent presque toute probabilité de visite humaine.